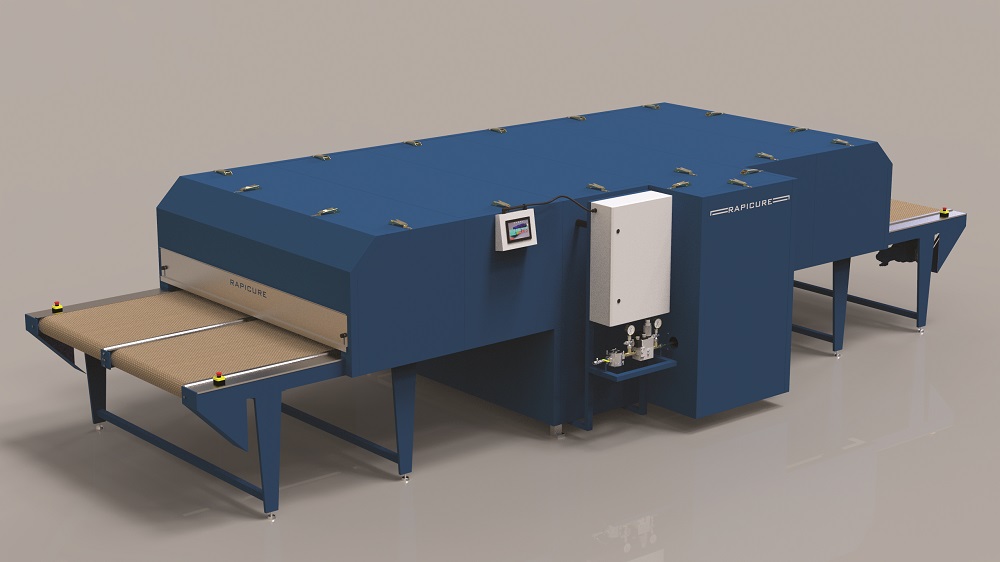

RAPICURE Gas Heated Textile Dryer

- RAPICURE has modular expandable design with additional heat chambers

- Tailor-made non standard solutions to meet every demand

- Many variations of belt width & heat chamber length

- The powerful blower of RAPICURE ensures a perfect curing

- Thanks to the “Actual Curing Time” feature; instead of belt speed value, the real curing time in the heat chamber is displayed on the operator’s control panel

- The speed and direction of the belts can be adjusted independently

- Using the “Temperature Calibration Page”, the dryer can be calibrated to show the actual garment temperature on the operator’s display

- The “Defect Seeking” system will display any fault on the operator’s panel and sound an alarm

- Emergency stop safety buttons are located both on in-feed & out-feed conveyors and on the electric panel as well

- The FIBERFLON brand belts are heat resistant up to 250°C (482°F) and both sides are Kevlar® by DuPont™

- Single-belt and double-belt models are available as well

- Stainless steel entry & exit openings are adjustable

- RAPICURE is operated by a single-touch button

- All failures can be read in ENGLISH on the operator’s display

- The PLC unit digitally controls and displays the process temperature and set temperature

- The “System Saver” feature means that, with a single touch it cools down and then shuts down automatically

- Due to its practical design, the filters only take 10 minutes to clean

- With its “Easy Cleaning Cover” on the blower, there is no need to uninstall the blower for cleaning

- High density rock-wool insulation and special design silicon gaskets reduce heat loss to a minimum

- The temperature can be set up to 200°C (392°F)

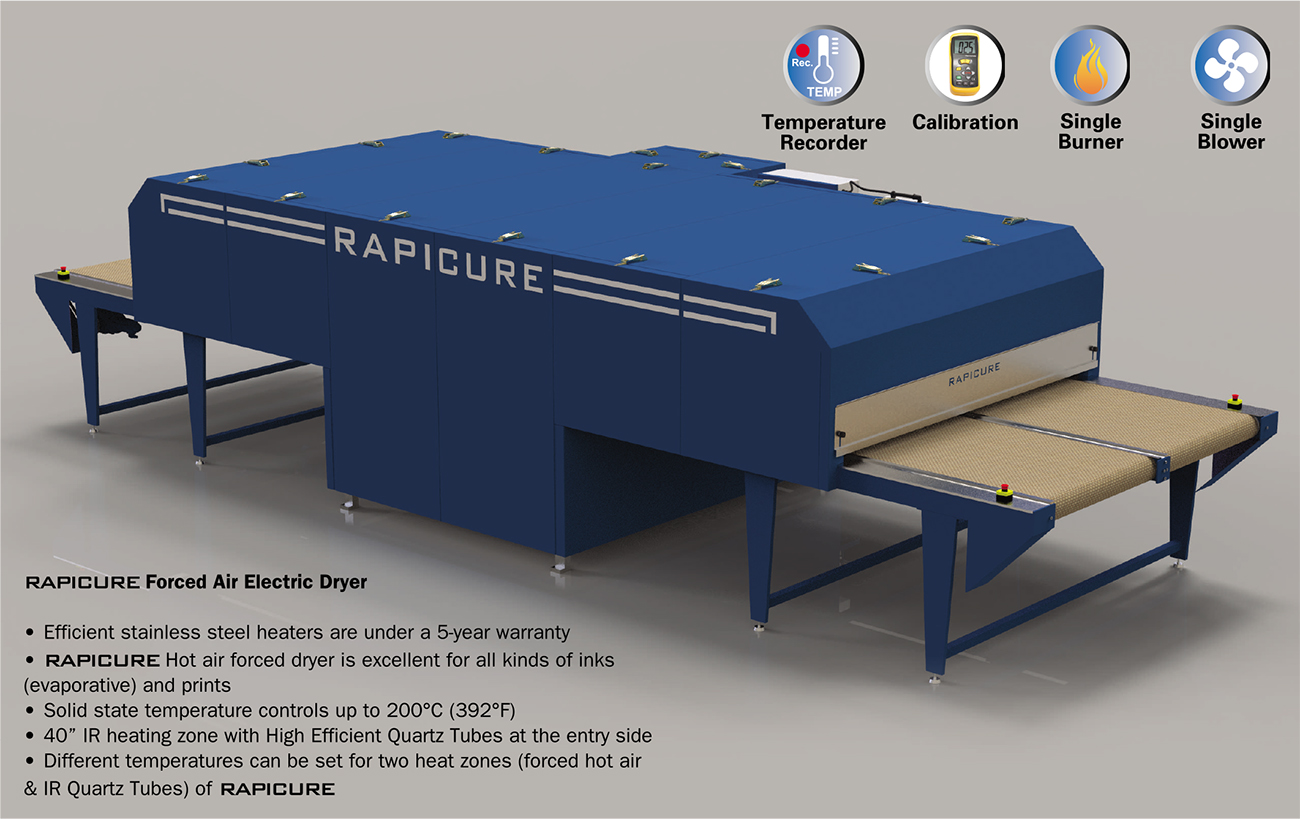

RAPICURE Forced Air Gas Dryer

- RAPICURE Gas Dryer performs 6 separate safety checks every time it is started

- Top quality control and gas equipment such as DUNGS, KROM SCHRODER, SIEMENS, SCHNEIDER, are used in RAPICURE

- The PLC unit organizes and controls; Max-Min Gas Pressure, Blower Air Pressure, High Temperature, Ignition and Flame Control, Double Gas Filter and Double Solenoid, Gas Pressure and Volume Regulator as well as the control of all Motor Failures and Failure Resets

- The fabric fibers and dust are burnt in the burner section, so the machine remains clean

- Due to its stainless steel atmospheric burner, it offers great economy

- An accurate SCHNEIDER PLC control system reduces gas consumption and ensures precise temperature control

Options

- Cooling system

- IR Ceramic Heating Zone

- Special assembly system fits through any door

- Special design inlet and outlet

- POWER SUPPLY for belts, so the belts will continue running 3-4 minutes in the event of energy failure