RAPIDRY IR Flash Cure Units

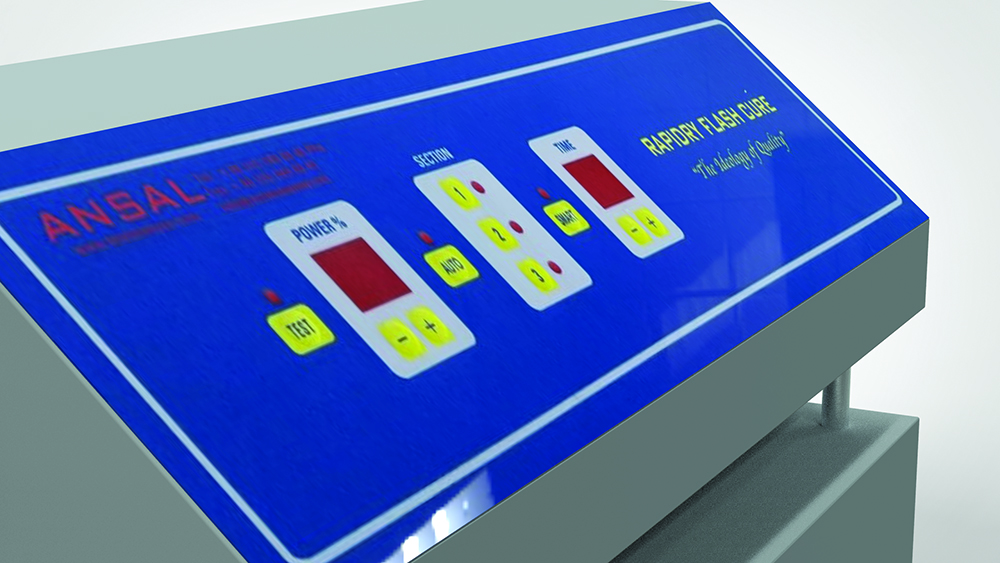

- The power of RAPIDRY can be adjusted digitally

- The curing duration is set in seconds, while operating the timer counts down the remaining time

- The lamps are divided into three zones, which can be operated independently or in any combination

- RAPIDRY started using its optical sensor switch or a signal from the automatic printing machine. (the communication cable with appropriate socket is an option)

- The special filament design lowers energy costs and to increase the life time

- Ultra-economic medium wavelength lamps reduce electricity comsumption

- The lamps have their own reflectors to increase the efficiency

- The stainless steel laser cut reflector is perforated; therefore, heated forced-air is obtained from the powerful blower

- The distance between RAPIDRY and the print can be adjusted manually

- Portable and easy to install

- Independent button to test-start

- The aluminum blower is EBM PAPST brand and made in Germany

- The powerful blower of RAPIDRY provides forced air to cure the ink rapidly

- The control head is cooled with a high efficiency aluminum heat sink instead of a fan, so all the electronic system remains clean

- RAPIDRY is user-friendly with two memory buttons on control panel

- Preheating function keeps the filament hot, and the preheating power can be adjusted on control board

- Maximum (total) power can be limited and locked on control panel